An Agile Approach to Building Your Vision: Step by Step

Conversation

We start with a conversation to understand your vision, goals, and challenges. This initial discussion is a collaborative ideation session where we explore possibilities, brainstorm ideas, and define the scope of your project. Your input drives the foundation of everything we create.

Proposal & Iterate

Based on our discussion, we provide a detailed proposal outlining the approach, timeline, and estimated costs. This ensures transparency and alignment, giving you a clear roadmap for how we’ll turn your idea into reality.

Design & Iterate

In the design phase, we refine your vision through a structured approach, moving from low-fidelity to high-fidelity representations:

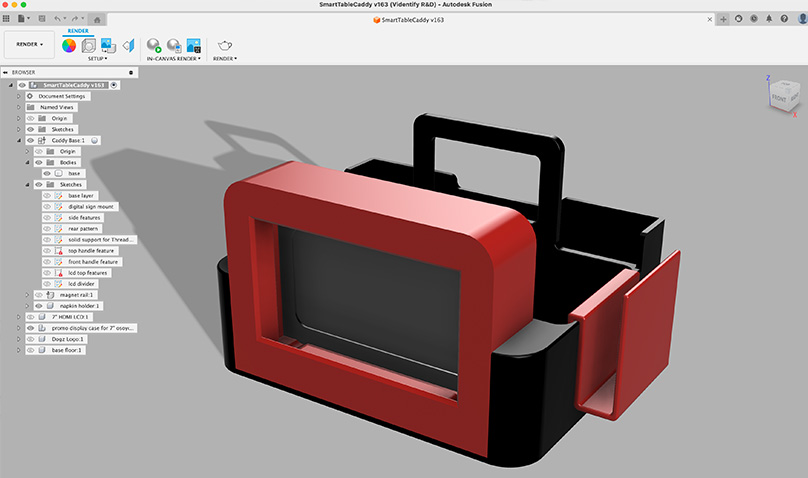

- Low-Fidelity Designs: We start with rough sketches, wireframes, or basic 3D models to explore ideas quickly and cost-effectively. This stage focuses on layout, structure, and functionality, ensuring alignment with your vision before delving into details.

- High-Fidelity Designs: Once the core concepts are validated, we transition to detailed renderings, polished prototypes, and fully interactive models. This step brings your project to life with realistic visuals, precise dimensions, and materials that closely represent the final product.

Review

Once the design is finalized, we create comprehensive specifications that serve as the blueprint for the build. This includes technical documentation, material selection, and precise details to guide the manufacturing or development process. Don't worry, there's still room to iterate after the initial prototype is created!

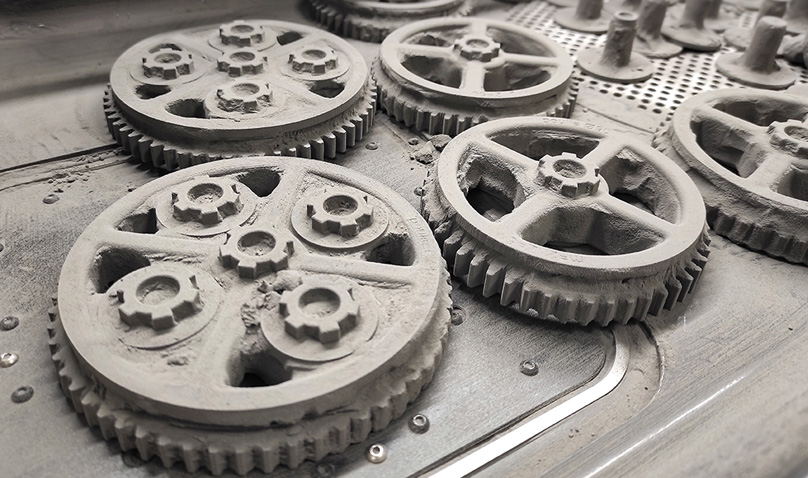

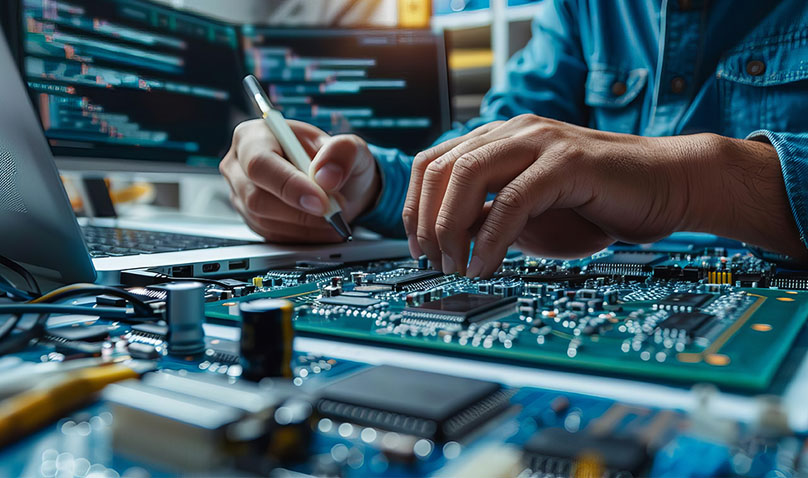

Build & Iterate

In the build phase, we combine additive manufacturing, subtractive techniques, and other innovative processes to create your project with precision and efficiency. A prototype is crafted for review, ensuring alignment with your vision before scaling to production. Whether it’s a single unit or a full batch, our tailored approach guarantees quality and performance at every step.

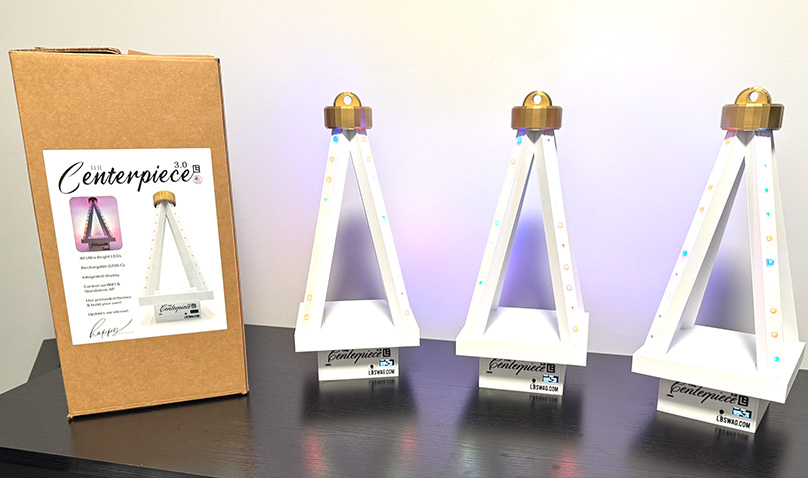

Deliver & Iterate

The final step ensures your project is delivered as envisioned. After rigorous quality checks, the completed product is prepared for deployment or use. Whether it’s a prototype, a single unit, or a full batch, we coordinate secure and efficient delivery, ensuring your project arrives ready to make an impact.

But delivery is just the beginning. We continue to work with you to iterate on the product, make improvements based on real-world feedback, and provide ongoing support to ensure its success in the field.